Imagine having a system that constantly adjusts itself to maintain optimal performance. That’s the magic of a PID controller. This powerful tool is essential in various industries, from robotics to HVAC systems, ensuring processes run smoothly and efficiently.

In this article, you’ll discover how PID controllers work and why they’re crucial for maintaining stability in dynamic environments. We’ll explore real-world examples that highlight their versatility and effectiveness. Have you ever wondered how your favorite gadgets keep everything in balance? The answer often lies within the principles of PID control.

What Is a PID Controller?

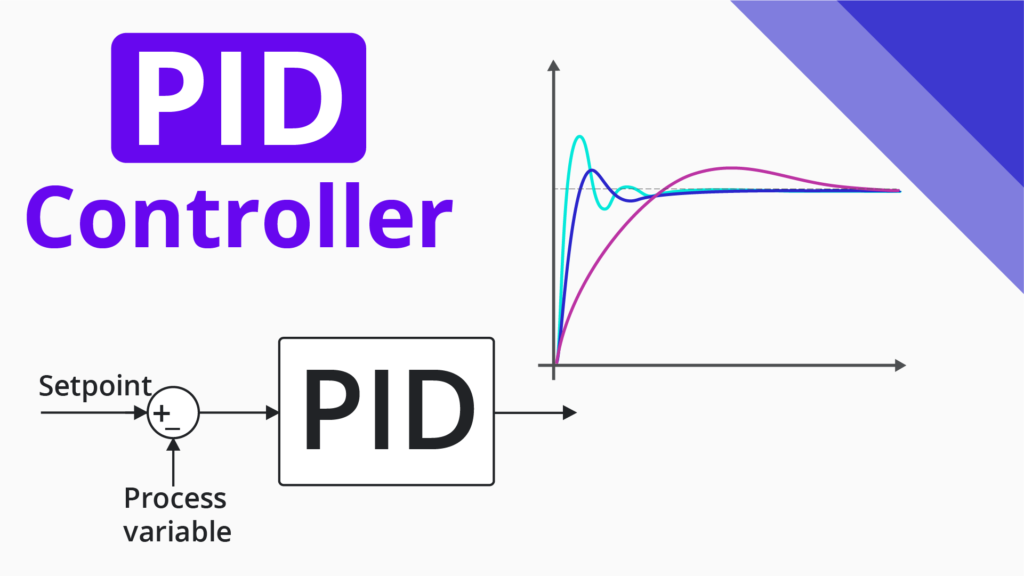

A PID controller, or Proportional-Integral-Derivative controller, is a crucial tool used in automation and control systems. It maintains desired output levels by adjusting system inputs based on error values. Understanding its components and functionality provides insight into its widespread applications.

Definition and Components

A PID controller consists of three key components: Proportional (P), Integral (I), and Derivative (D).

- Proportional: This component reacts to the current error, providing an output that is proportional to the magnitude of that error.

- Integral: This part accumulates past errors over time, addressing any sustained discrepancies from the desired setpoint.

- Derivative: This element predicts future errors based on the rate of change of the error, allowing for quicker responses.

These combined elements work together to ensure smooth control across various systems.

How It Works

The operation of a PID controller involves calculating an error value as the difference between a desired setpoint and a measured process variable. The formula for PID control can be expressed as:

[

text{Output} = K_p cdot e(t) + K_i cdot int_0^t e(tau) dtau + K_d cdot frac{de(t)}{dt}

]

Where:

- ( K_p ), ( K_i ), and ( K_d ) are tuning parameters for each component.

- ( e(t) ) represents the current error at time ( t ).

This equation allows you to adjust process inputs dynamically based on current conditions. By fine-tuning these parameters, you enhance performance in systems like temperature control in HVAC units or speed regulation in motors.

Types of PID Controllers

PID controllers come in various types, each suited for different applications and environments. Understanding these types helps you select the right controller for your specific needs.

Standard PID Controllers

Standard PID controllers are the most common type used in industrial automation. They utilize fixed parameters for proportional, integral, and derivative actions. This simplicity makes them ideal for stable processes. For instance, a temperature control system in an HVAC unit often employs a standard PID controller to maintain consistent temperatures by adjusting heater or cooler outputs.

Adaptive PID Controllers

Adaptive PID controllers adjust their parameters in real-time based on changing process conditions. This flexibility allows them to respond effectively to varying dynamics. For example, in robotic systems that encounter unpredictable obstacles, adaptive PID controllers can modify their behavior to ensure smooth navigation while maintaining accuracy in movement.

Applications of PID Controllers

PID controllers play a vital role in various industries, ensuring processes run smoothly and efficiently. Here are some common applications where PID controllers excel.

Industrial Automation

In industrial automation, PID controllers help maintain consistent process variables. For example:

- Temperature Control: In chemical plants, maintaining specific temperatures is crucial. A PID controller adjusts heating elements based on temperature deviations.

- Pressure Regulation: Oil refineries use PID controllers to manage pressure levels within pipelines. Fluctuations can lead to safety hazards or inefficiencies.

- Flow Control: Water treatment facilities utilize PID controllers to regulate flow rates, ensuring the right amount of water is processed at all times.

These examples demonstrate how PID controllers enhance productivity and safety in industrial environments.

Robotics

In robotics, precision is key for effective operation. Examples include:

- Motion Control: Robots in manufacturing lines rely on PID controllers to achieve accurate movements, adjusting their speed and position dynamically.

- Stabilization Systems: Drones employ PID controllers for stabilization during flight, compensating for wind or other disturbances automatically.

- Automated Guided Vehicles (AGVs): AGVs use these controllers to navigate complex environments by continuously fine-tuning their paths based on sensor feedback.

Each application showcases the essential role of PID control in achieving high-performance robotics systems.

Advantages and Disadvantages of PID Controllers

PID controllers offer several benefits, but they also have some limitations. Understanding these can help you leverage their strengths while being aware of potential challenges.

Pros

PID controllers provide precise control. They adjust system inputs based on real-time error values, ensuring minimal deviation from the desired setpoint. This precision is crucial in applications like temperature regulation in HVAC systems.

PID controllers enhance stability. By continuously fine-tuning outputs, they reduce overshoot and oscillations. This characteristic makes them ideal for industrial processes where consistent performance is necessary.

They are versatile across industries. From robotics to chemical processing, PID controllers adapt well to various environments. You’ll find them controlling everything from motor speed in manufacturing to fluid levels in water treatment facilities.

Cons

Tuning can be complex. Setting optimal parameters requires expertise and experimentation. If tuning isn’t done correctly, it may lead to poor performance or instability.

PID controllers struggle with non-linear systems. For processes that exhibit significant variability or require adaptive responses, traditional PID implementations may not suffice. In such cases, other advanced control strategies might be more effective.

The integral component can cause lag. While accumulating past errors helps improve accuracy over time, it can introduce a delay in response during rapid changes. This lag could affect systems requiring immediate adjustments.