Ever wondered how your favorite gadgets and vehicles are made? The answer often lies in the world of OEM—Original Equipment Manufacturer. This term plays a crucial role in various industries, from electronics to automotive, shaping the products you use every day. Understanding OEM can unlock insights into product quality, reliability, and even pricing.

What Is OEM?

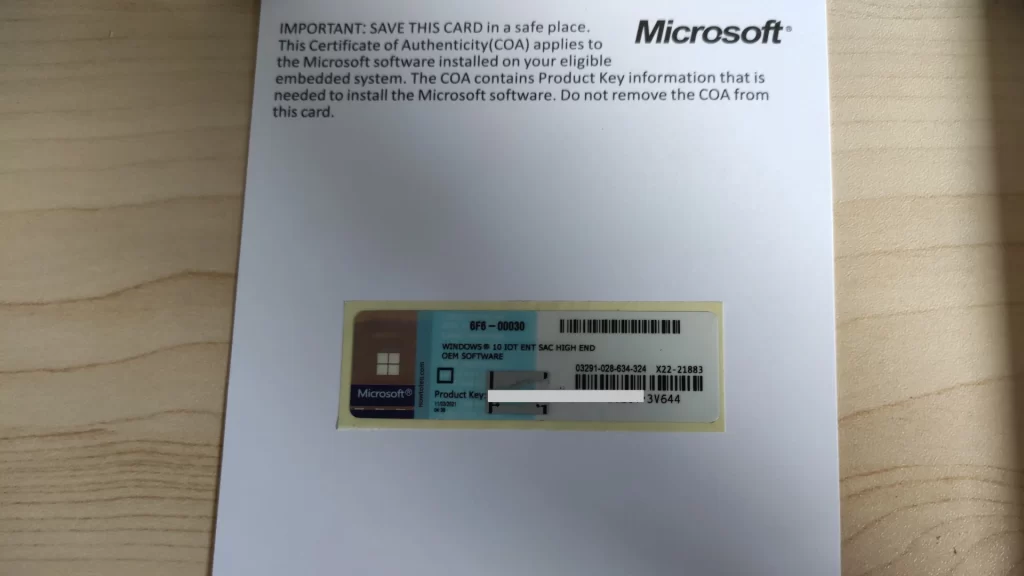

Original Equipment Manufacturer (OEM) refers to a company that produces parts or equipment that may be marketed by another manufacturer. This concept plays a crucial role in various industries, especially electronics and automotive. Understanding OEM helps you grasp its influence on product quality, reliability, and pricing.

Definition of OEM

An OEM is a company that manufactures products or components that are sold under another brand’s name. For example, if Company A designs a car but relies on Company B for the engine, Company B acts as the OEM for that engine. You often see this arrangement in consumer electronics where well-known brands outsource production to specialized manufacturers.

History of OEM

The history of OEM dates back several decades. Initially, many companies aimed to reduce costs by outsourcing production. By doing so, they leveraged the expertise of specialized manufacturers without investing heavily in manufacturing facilities. Today, the trend continues as companies prioritize efficiency and focus on their core competencies while relying on OEMs for high-quality components at competitive prices.

Recognizing the significance of OEM helps you appreciate how products reach your hands with guaranteed quality and performance standards backed by reliable partnerships between manufacturers.

Types of OEM

Understanding the different types of OEM helps in recognizing their roles across industries. Primarily, two categories stand out: Manufacturer OEM and Private Label OEM.

Manufacturer OEM

Manufacturer OEMs create products or components that carry another company’s brand name. For instance, Foxconn manufactures devices for Apple, while Bosch produces automotive parts for various car brands. These partnerships allow companies to leverage specialized expertise without investing heavily in production facilities. This model enhances efficiency and maintains quality standards.

Private Label OEM

Private Label OEMs produce goods that retailers sell under their own brand names. Retail giants like Walmart partner with manufacturers to offer products exclusive to their stores. Examples include grocery items or clothing lines created specifically for a retailer’s market. This approach allows businesses to differentiate themselves and cater directly to consumer preferences while keeping costs manageable.

Advantages of OEM

OEMs offer several key advantages that enhance both production processes and overall product quality. Understanding these benefits helps you appreciate the value of choosing OEM partnerships.

Cost Efficiency

Cost efficiency stands out as a primary advantage of using OEM. By outsourcing production, companies can reduce manufacturing costs significantly. For instance, electronics manufacturers often rely on OEMs in regions with lower labor costs, such as Southeast Asia. This approach allows them to allocate resources more effectively while maintaining competitive pricing for consumers. Additionally, bulk purchasing of materials through OEM partnerships further lowers expenses.

Customization Options

Customization options provided by OEMs cater to specific market needs. Companies can collaborate with their OEM partners to develop tailored products that meet unique consumer demands. For example, automotive brands may work with an OEM to design specialized components or features that distinguish their vehicles from competitors’. Such flexibility ensures products align closely with brand identities and customer preferences, enhancing market appeal and driving sales.

By leveraging cost efficiency and customization options, you can better navigate the complexities of modern manufacturing while ensuring high-quality products for your consumers.

Disadvantages of OEM

OEM partnerships, while beneficial, come with notable disadvantages. Understanding these challenges helps you make informed decisions when considering OEM options.

Quality Control Issues

Quality control can become a concern in OEM arrangements. When outsourcing production, maintaining consistency across products proves challenging. For instance, if an OEM manufacturer lacks rigorous quality standards, defects may arise. This situation could lead to customer dissatisfaction and brand damage. Ensuring that suppliers adhere to strict quality checks is essential for safeguarding your brand’s reputation.

Dependency on Suppliers

Dependency on suppliers represents another significant drawback of using OEMs. Relying heavily on an external company for crucial components or products creates vulnerabilities in your supply chain. If the supplier faces disruptions—like natural disasters or labor strikes—you might experience delays or shortages. Diversifying your supplier base can mitigate these risks, but it requires careful planning and management to ensure continuity in production and availability of goods.